Overview

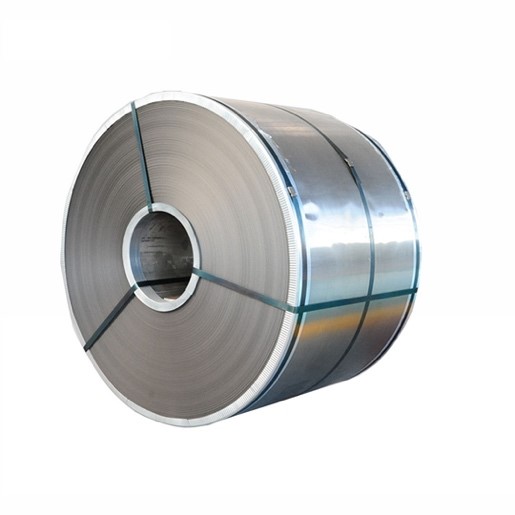

Arami Group is one of the top suppliers of galvanised coils in the Middle East and Africa. We supply special high-grade galvanised coils A3 (400) for a wide range of applications — including floor slabs, stairs, and roof construction. Our commitment to customer service assures responsive and knowledgeable assistance when you need it. Arami Group Team has the expertise and experience to help you meet today’s tough challenges with ground breaking innovation for your business needs.